The Duravant family of operating companies serve the food processing, packaging and material handling segments.

The Evolution of Industrial Filling Machines in Global Supply Chains

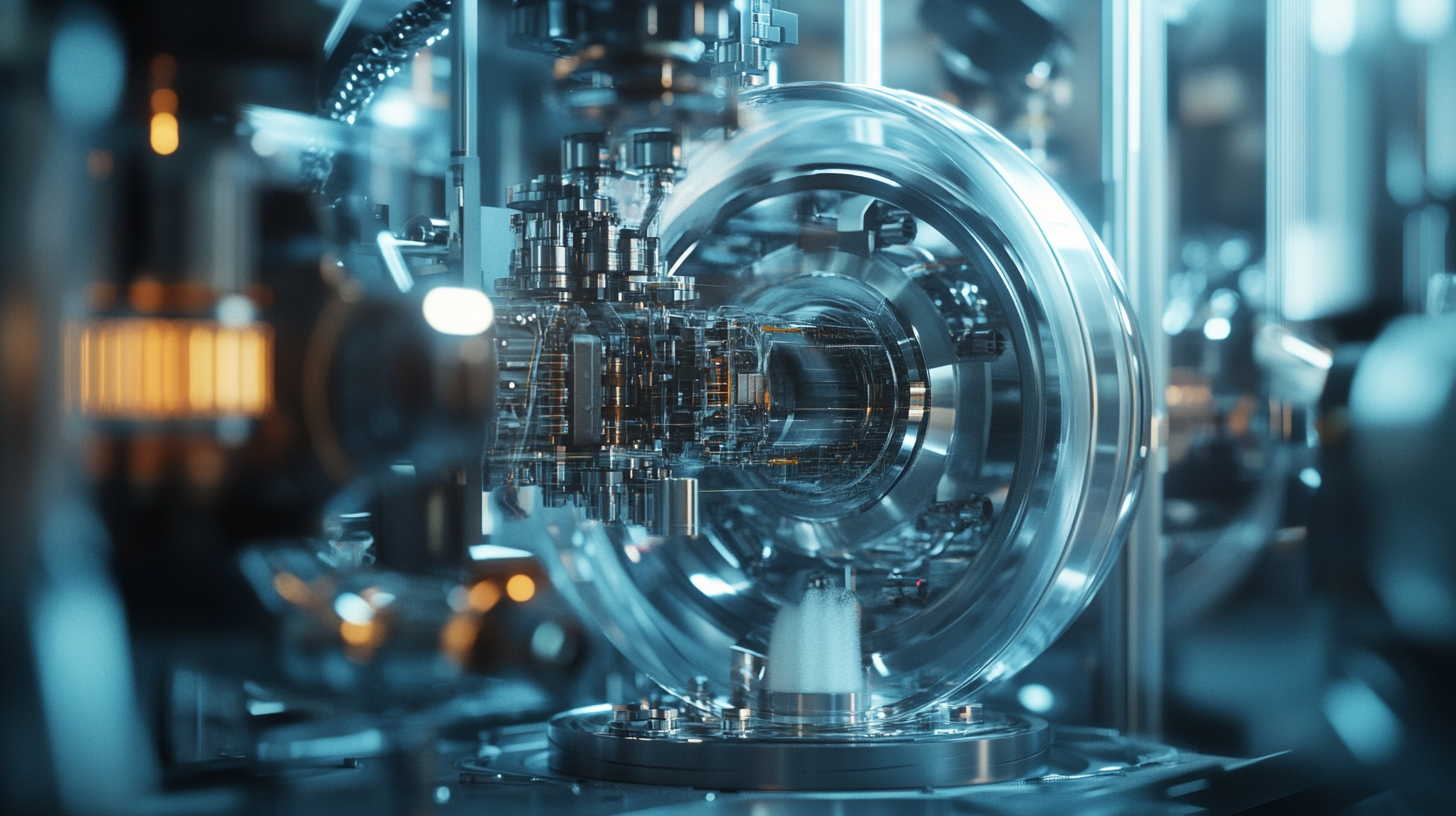

The evolution of industrial filling machines has played a pivotal role in transforming global supply chains, enhancing efficiency, and ensuring precision in various industries. As businesses scale up production to meet growing consumer demands, the integration of advanced industrial filling machines has become imperative. These machines have undergone significant innovations over the years, transitioning from manual operations to highly automated systems that cater to diverse packaging requirements. This shift is not only about improving speed but also about maintaining quality and consistency, which are essential in today’s competitive market.

As we delve into the intricacies of industrial filling machines, it becomes clear how they have adapted to the changing landscape of global commerce. The rise of e-commerce and the demand for quick turnaround times have pushed manufacturers to invest in cutting-edge technologies. This blog will explore the historical development of industrial filling machines, their impact on supply chain dynamics, and the emerging trends that promise to shape their future. Understanding this evolution is critical for businesses aiming to enhance their operational capabilities and stay ahead in the ever-evolving market.

The Historical Development of Industrial Filling Machines in Supply Chains

The historical development of industrial filling machines within global supply chains reflects significant advancements in technology and shifts in the market landscape over the decades. Initially, filling machines served rudimentary roles, focusing on manual processes prevalent during the industrial revolution. However, with the rise of automation and the increasing demand for efficiency, these machines evolved into sophisticated systems capable of handling varied products and enhancing production rates. This evolution not only improved operational efficiency but also positioned filling machines as pivotal components in the broader supply chain dynamics. As industrializing economies, notably in Asia, began to innovate and adopt advanced technologies, the filling machine market witnessed robust growth. Today, market reports indicate a strong uptrend, with projections showing a growth from $8.26 billion in 2024 to $8.72 billion in 2025. This increase can be attributed to advancements in machinery capabilities, including precision filling, adaptability to different product types, and integration with digital supply chain management systems. However, challenges persist, particularly as geopolitical tensions and potential trade tariffs loom, reminiscent of the disruptions experienced during the 2018-19 trade conflicts. Moreover, the circularity in supply chains is becoming a focal point for filling machines, pushing manufacturers to innovate not just in efficiency, but also in sustainability practices. As the demand for eco-friendly packaging surges, filling machines are being designed to minimize waste and improve recyclability. This not only aligns with global sustainability goals but redefines how filling machinery connects with logistics and distribution, ensuring that manufacturers can meet the evolving needs of conscious consumers.

Key Technological Innovations Transforming Filling Machine Efficiency

The filling machine industry has seen remarkable transformation driven by key technological innovations, significantly enhancing efficiency across global supply chains. According to a report by Allied Market Research, the global filling machines market was valued at $5.92 billion in 2020 and is expected to reach $9.48 billion by 2027, growing at a CAGR of 6.9%. This growth can largely be attributed to advancements in automation and smart technologies that improve throughput and reduce downtime.

One of the most notable innovations is the integration of IoT capabilities into filling machines. This connectivity allows for real-time monitoring of machine performance and predictive maintenance, reducing the risk of unexpected failures. A McKinsey report highlights that companies implementing IoT solutions can achieve a reduction in maintenance costs by up to 30%, enhancing overall operational efficiency. Additionally, smart filling machines can gather and analyze data to optimize filling processes, leading to more accurate fill volumes and less waste.

Moreover, advancements in robotics and artificial intelligence are transforming the operational landscape. Machines equipped with AI algorithms can adapt to varying product types and sizes without extensive manual reconfiguration, increasing flexibility in production lines. According to a 2022 report from MarketsandMarkets, robotic filling machines are projected to grow at a rate of 8.5% annually, reflecting increasing adoption in various sectors including food and beverage, pharmaceuticals, and cosmetics. These technologies not only enhance speed but also ensure compliance with stringent industry regulations, ultimately driving higher quality and consumer satisfaction.

Impact of Globalization on Filling Machine Design and Functionality

The advent of globalization has significantly reshaped the design and functionality of industrial filling machines. As businesses expand their reach across borders, they require equipment that not only meets diverse regulatory standards but also caters to varied consumer preferences. This has led manufacturers to innovate, crafting filling machines that are more adaptable and customizable, enabling seamless integration into multifaceted supply chains.

One of the key changes driven by globalization is the need for versatility in filling technology. Modern filling machines are now equipped to handle a wide array of products and packaging types, from liquids to solids, and various container shapes and sizes. This flexibility allows companies to quickly pivot in response to market demands, whether that be introducing new products or adjusting to shifts in consumer behavior. As a result, the machines are built with a modular approach, allowing for easy upgrades and modifications as market needs evolve.

Additionally, the impact of globalization extends to the automation and connectivity of filling machines. The push for efficiency and reduced operational costs has compelled manufacturers to incorporate advanced technologies such as IoT (Internet of Things) connectivity, which allows for real-time monitoring and optimization of filling processes. This digital transformation not only enhances productivity but also provides valuable data analytics, enabling companies to make informed decisions that influence their logistics and supply chain strategies. Through these advancements, industrial filling machines are becoming an integral part of a global ecosystem, ensuring that businesses can thrive in an ever-changing market landscape.

Sustainability Trends Driving Changes in Industrial Filling Technologies

The industrial filling machine sector is undergoing a pivotal transformation driven by sustainability trends that align with global supply chain demands. According to a report by the International Society for Pharmaceutical Engineering (ISPE), sustainable manufacturing practices are no longer optional; they are becoming regulatory requirements. For instance, 61% of companies in the food and beverage industry are now focusing on waste reduction and energy efficiency as key components of their operational strategies.

Advancements in filling technology are responding to these sustainability pressures with innovations such as biodegradable materials and energy-efficient systems. The 2023 Global Market Insights report suggests that the demand for eco-friendly filling machines is set to surge, forecasting a compound annual growth rate (CAGR) of 9.3% through the next five years. Manufacturers are increasingly investing in automation and smart technologies that not only streamline processes but also significantly reduce resource consumption.

Furthermore, circular economy practices are influencing the design of filling machines. According to McKinsey's recent analysis, firms that integrate sustainable modes of operation into their production lines can expect reduced compliance costs by 20-30%. As industries strive to meet both regulatory and consumer demands for sustainability, the evolution of filling technologies reflects a robust commitment to environmental stewardship, ultimately reshaping supply chain strategies on a global scale.

Future Predictions: The Role of Automation in Filling Machine Evolution

The rapid evolution of industrial filling machines is largely driven by automation, aiming to meet the increasing demand stemming from private label growth in various markets. According to industry reports, the flexible and cost-effective cup filling machines are becoming essential, capable of handling diverse products, sizes, and materials. This adaptability is critical in addressing the shifting consumer preferences and expectations for customized packaging, highlighting the necessity for automation in contemporary manufacturing settings.

Recent advancements in technology, particularly generative AI, are reshaping the parameters of automation in filling machines. As generative AI expands its capabilities, the potential applications of this technology in the filling process are unprecedented. From optimizing filling speeds to enhancing precision and reducing waste, AI-driven solutions facilitate a more efficient operational framework for manufacturers. Industry insights suggest that integrating such advanced tools not only streamlines production processes but also significantly cuts operational costs, making it a strategic investment for businesses aiming to thrive in a competitive landscape.

Moreover, the push towards sustainability within the manufacturing sector is nudging companies to adopt automated solutions that prioritize eco-friendly practices. Research indicates that automation can assist in minimizing material waste and energy consumption, thus aligning with global sustainability goals. As the demand for efficient, environmentally conscious packaging solutions grows, the role of automation in the evolution of filling machines will undoubtedly intensify, shaping the future of supply chains worldwide.